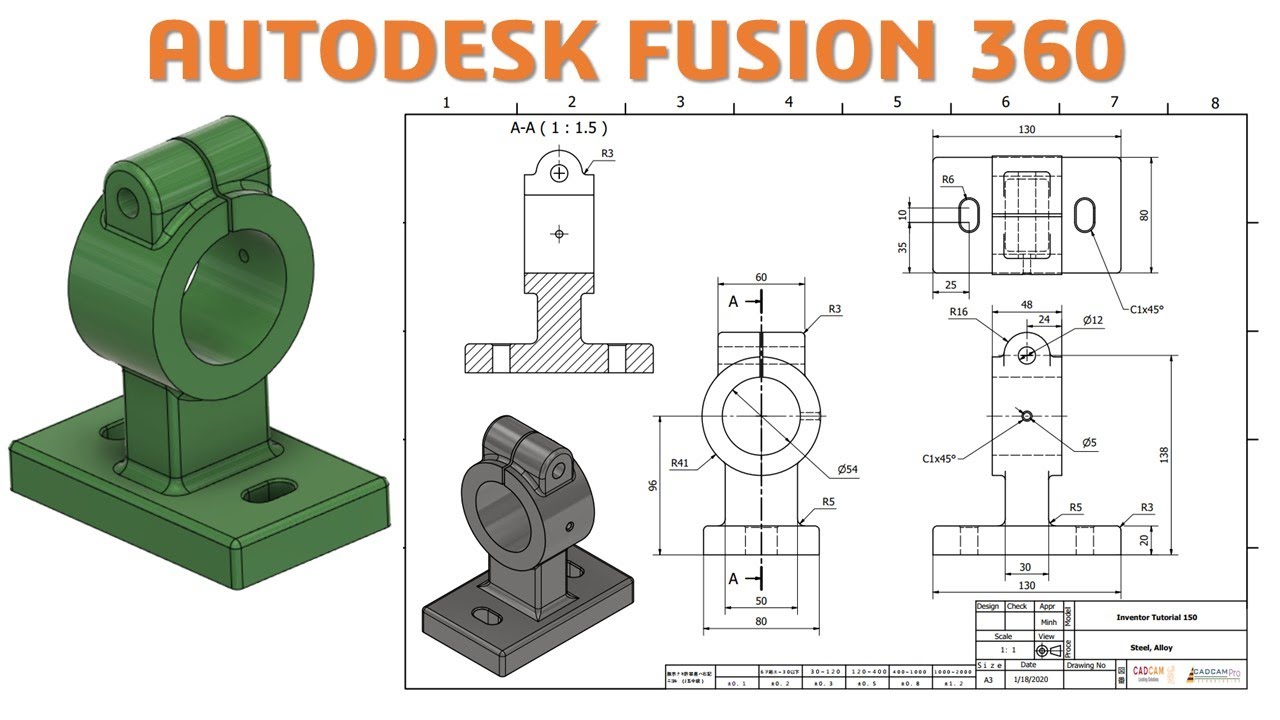

In Fusion360 or Solidworks, the first thing you do to create your part is make a sketch. Fusion360 and Solidworks: Focus on the Sketch Similar to human language, the more you process a file through a digital translator, the less legible it will get (Google translate from English to Spanish then back to English to see what I mean!).

In most cases, the file will not be useable. If you attempt to convert a file from one form to another using an online converter, app or plugin, weird things can happen. If your software doesn’t save-as or export the common file types we accept, that’s a sign that there will be problems with the file you send us. eps option instead.ĮPS – Save-as from Adobe Illustrator or Corel Draw Don’t Use Conversion Apps If your program has an option to export as an Illustrator file, but it’s not Illustrator, try an. Save-as from QCAD or other popular 2D CAD programsĭWG – Save-as from AutoCad, Revit, ArchiCADĪI – Save-as from Adobe Illustrator only. The file types we accept are:ĭXF – Exported from a sketch in Solidworks or Fusion360. The software you use will determine the file type that you send to us. If you’re working in the following programs, your 2D vector files will likely not be optimized for laser cutting, and are not supported by our process:

Some 3D-centric programs offer an option for 2D exporting, but they do not define 2D shapes accurately or efficiently. Expensive, but a reduced cost option is available with an EAA membership or if you are a student. If you are good at Solidworks, you’ll never be unemployed. An accurate Bill of Materials itemizes the components of an assembly to guarantee the discovery of missing parts and prevent costly delays.This is the industry standard. Use assembly exploded views to define the assembly order and methods.

Sticking with the race car example, once it’s time for assembly, you can use the assembly drawings tool to tell the manufacturer the number of components your design includes. The hatching tool allows you to see which areas of the race car’s chassis are hollow, revealing how structurally stable the chassis is at specific locations. Adding hole callouts to your drawings is also important as it delineates the hardware needed for the holes and properly communicates design intent to the manufacturer. Using drawing tools in SOLIDWORKS can detail every necessary drawing view to show the manufacturer all angles of the chassis. For race cars, it’s crucial to manufacture the chassis correctly because a small design error can compromise its integrity. For example, if you’re designing a race car, you can use SOLIDWORKS to convey the necessary design information to the manufacturer.

0 kommentar(er)

0 kommentar(er)